- 9:00 am to 6:00pm

Chemical

- Home

- Chemical

Chemical Filtration

We understand the impact improper filtration can have on the chemical products you produce and the overall adverse impact that substandard filtration can have on your business.

You Can Rely On Us To Solve Your Unique Chemical Processing Challenges

Our team of filtration specialists has a long history of solving some of the most complex and diverse challenges for leaders in the Chemical Manufacturing industry. Whether you are trying to improve manufacturing efficiency or improve overall product quality, the ARNS Filter team will partner with you and leverage our technical knowledge in chemical processing to help you achieve your goals.

Applications:

- Bleach

- Carbon Black

- Dyestuffs

- Hydrogen Peroxide

- Intermediates

- Raw Materials

- Potash

- Titanium Dioxide

Filtration Solutions for the Chemical Industry

In the chemical industry, it is critical to filter process components to prevent particulate and microbial contamination, helping ensure product sterility and quality. ARNS Filter’s product solutions help protect the process from contaminants while extending service life and reducing operations costs. ARNS Filter designs and manufactures filter elements and vessels that are widely used in the chemical industry and our years of industry expertise will help to optimize your manufacturing process.

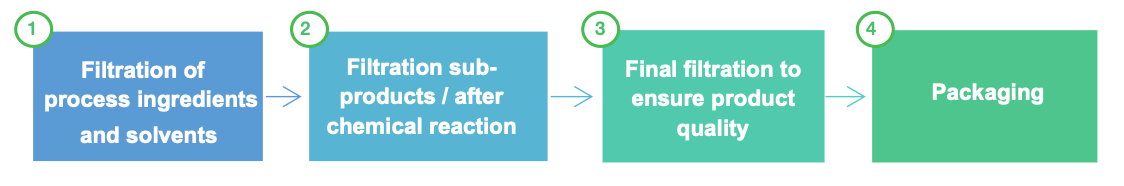

Typical Chemical Process

Many of the finished goods in the chemical industry are made using the same process equipment. As a result impurities from one process stream could negatively impact neighboring systems which can lead to unwanted contamination, additional clean-in-place measures, product loss, and decreased revenue. Efficient filtration systems positioned in critical chemical process locations can help mitigate risk by increasing particulate removal efficiency, improving effluent quality, and reducing necessary maintenance.

Filtration of Chemical Process

Ingredients

The first step in the chemical production process is filtering the process ingredients to purify solvents and remove unwanted particulate or pollutants from organic and inorganic products which could reduce the efficiency of the chemical reaction. This step will also reduce the production of sub-products. When filtering organic and inorganic process ingredients, we recommend using our pleated depth cartridge (PP-Series) with a 0.2-micron rating and a PES membrane cartridge for microbial retention. ARNS Filter recommends a pre-filtration step to prevent the pleated membrane cartridges from clogging too quickly in case of high solid loading. For solvent filtration, we recommend using our PTFE or Nylon 6,6 cartridges depending on the aggressiveness of the solvent and chemical compatibility with the materials of construction.

Filtration After Chemical Reaction

During the chemical reaction, sub-products are often generated and need to be retained. Retention of these sub-products will help improve the purity of the final product. For this step, we recommend using ARNS Filter’s pleated depth cartridge (GHLS-Series) to remove what are often deformable particles. Also, the microglass pleated cartridge (FG-Series) is an ideal solution for removing colloids due to an inherent positive charge within the filter media.

Filtration After Chemical Reaction

During the chemical reaction, sub-products are often generated and need to be retained. Retention of these sub-products will help improve the purity of the final product. For this step, we recommend using ARNS Filter’s pleated depth cartridge (GHLS-Series) to remove what are often deformable particles. Also, the microglass pleated cartridge (FG-Series) is an ideal solution for removing colloids due to an inherent positive charge within the filter media.

Final Chemical Filtration

Before conditioning and preparing for packaging, a final filtration step is recommended to ensure product purity and quality. For this stage, we recommend using our high flow pleated cartridge (HFB-Series). Due to the inside-to-outside flow design, all contaminants are captured on the inside of the element, avoiding potential contamination of the filtered products during change-out. With up to 48.5 square feet of media, the HFB-Series reduces change-out frequency and employee exposure to chemicals.

Literature

Fine Chemical Filtration Application

In the chemical industry, it is critical to filter process components to prevent particulate and microbial contamination, helping ensure product sterility and quality. Learn how ARNS Filter’s product solutions help protect the process from contaminants while extending service life and reducing operations costs.

Tank Vent/Gas Filtration Application

In the chemical industry, it is critical to filter tank vents and process gases. Learn how ARNS Filter’s product solutions help protect the process from contaminants while extending service life and reducing operations costs.

Chemical Filtration

Application

Production of cleaning and sanitizing agents, adds a level of complexity to filtration not present in most other applications. Learn what type of filter material offerings are recommended for treating these elements.

Polyvinylpyrrolidone (PVP)

Chemical Filtration

Poor filtration can significantly impact the quality of products like PVP. Learn how ARNS Filter helped a customer improve particulate and endotoxin removal efficiencies while elevating product quality

High Purity Case

Study

Discover how a manufacturer was able to exceed their customers’ particulate requirements and remove all detectable endotoxins consistently by implementing ARNS Filter’s product solution.

Contact

- Infiflow ARNS Technofilters Pvt. Ltd.

- RACHETA SOCIETY NIGDI, Yamuna nagar, Pune City, Pune- 411044, Maharashtra

- © Copyright 2025, arnstechnofilters.com