- 9:00 am to 6:00pm

Cosmetics

- Home

- Cosmetics

Cosmetics Filtration

ARNS Filter offers a diverse line of high-purity liquid filtration products capable of handling bulk solids removal, clarification, fine particulate removal, and even sterilization in the cosmetic industry.

Cosmetic Industry Filtration

In recent months, many cosmetics companies have pivoted from producing face creams and perfumes to disinfectants and hand sanitizers. The switch has required manufacturers to make some drastic changes to existing production lines, but the role that filtration plays has remained constant – to maximize cosmetic product cleanliness, clarity, and consistency.

Filtration Solutions for the Chemical Industry

In the chemical industry, it is critical to filter process components to prevent particulate and microbial contamination, helping ensure product sterility and quality. ARNS Filter’s product solutions help protect the process from contaminants while extending service life and reducing operations costs. ARNS Filter designs and manufactures filter elements and vessels that are widely used in the chemical industry and our years of industry expertise will help to optimize your manufacturing process.

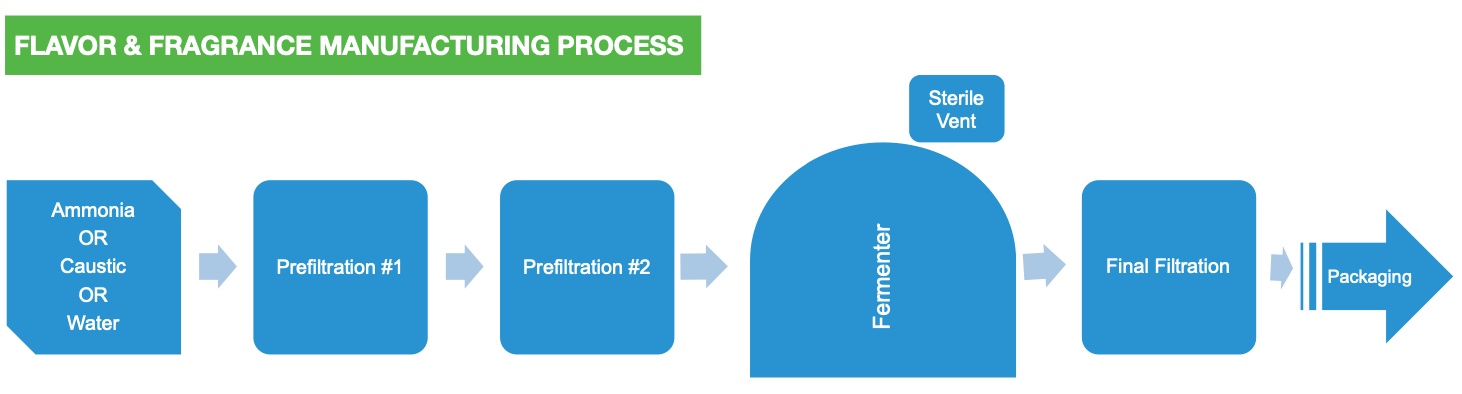

Typical Cosmetic Filtration Process

Prefiltration

ARNS Filter recommends using pleated depth cartridges for both. For #1 we recommend a 5.0-micron cartridge and for #2 we recommend a 1.0-micron cartridge.

Final Filtration

ARNS Filter recommends using a pleated depth cartridge at 0.2 microns for

the final filtration.

Cosmetic Production Filtration Products

Pleated Depth Cartridges

The multi-layer, fiber-based medias provide true depth-loading for high-efficiency removal at low micron ratings. Pleated depth cartridges design increases surface area which in turn, increases loading capacity and allows for higher flow rates. In a typical process flow, used as a prefilter to pleated membranes or as a polishing element to depth style medias.

Pleated Membrane Cartridges

Extremely high removal efficiencies allow for the removal of particulate and microbial contaminants. Multiple media and grade options are available to optimize a filtration train for the most demanding applications in liquid and air filter manufacturing. In a typical process flow, used as a prefilter to final polishing membranes or in a final filtration step to remove microbial contaminants.

Contact

- Infiflow ARNS Technofilters Pvt. Ltd.

- RACHETA SOCIETY NIGDI, Yamuna nagar, Pune City, Pune- 411044, Maharashtra

- © Copyright 2025, arnstechnofilters.com