- 9:00 am to 6:00pm

Beer Filtration

- Home

- Beer Filtration

Beer Filtration

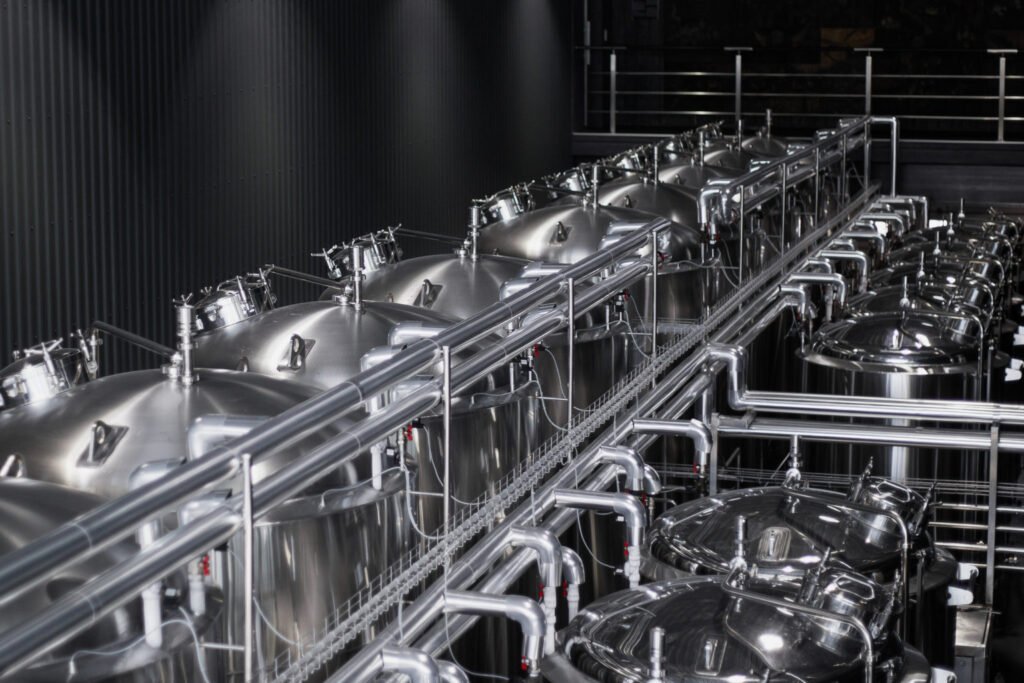

ARNS Filter provides beer filtration solutions across the brewing process. We provide filters to some of the world’s leading beer producers.

Beer Filtration and Clarification Solutions

As a premier supplier of depth, pleated depth, and pleated membrane cartridges and vessels, ARNS Filter is your one-stop solution for all your brewery filtration needs. Filtration is a crucial step in the brewing process. There are many types of beer, but the fundamental steps of brewing beer are shared across national and cultural boundaries. Brewing requires critical process operations to ensure the integrity of the brewing process and to consistently produce the perfect beer. A proper filtration system is critical in ensuring the biological safety, quality, and shelf-life of the product, as well as protecting process equipment. ARNS Filter designs and manufactures vessels and filter elements used in the brewing industry. Our expertise enables us to optimize your brewery.

Bulk Brewery Filtration Solutions

ARNS Filter operates on 3 key stages of beer production. First, is a bulk filtration step. After fermentation and aging solids and yeast must be removed to make the beer visually clear. For this step,we will hit on clarification solutions.

Beer Clarification

The next step ARNS Filter can improve your brewing process is clarification. Depending on beer composition (solid content, turbidity, microorganisms contents), we recommend using ARNS Filter’s PLATED MICROGLASS CARTRIDGE (FG & HFFG Series) and/or PLATED POLYPROPYLENE CARTRIDGE (PP & HFPP series) with a pore size rating of 1 to 3 microns. Moreover, the FG-SERIES offers a low-pressure drop, high load capacity, and efficiency while assisting in haze removal due to the media’s inherent positive charge. This step also protects the membrane filter from being overloaded with particles and prematurely clogging. Then we move on to the preservation and bottling steps.

Beer Clarification

The next step ARNS Filter can improve your brewing process is clarification. Depending on beer composition (solid content, turbidity, microorganisms contents), we recommend using Global Filter’s PLATED MICROGLASS CARTRIDGE (FG & HFFG Series) and/or PLATED POLYPROPYLENE CARTRIDGE (PP & HFPP series) with a pore size rating of 1 to 3 microns. Moreover, the FG-SERIES offers a low-pressure drop, high load capacity, and efficiency while assisting in haze removal due to the media’s inherent positive charge. This step also protects the membrane filter from being overloaded with particles and prematurely clogging. Then we move on to the preservation and bottling steps.

Beer Preservation

Lastly, before bottling, the third and final step that ARNS Filter can help your brewery with is to provide clarity to the beer while removing residual yeasts, haze, and microbial contaminants that can potentially induce bottle fermentation, haze reformation, and that would interfere with beer preservation. For microbial contaminant removal, .45 micron or 0.8 micron rated PES MEMBRANE CATRIDGE are recommended. Removing the microorganisms provides a stable product, free from microbial contaminants.

Filtration Products for Breweries

FG-SERIES

Our FG-Series is suitable for colloid filtration, and food contact and does not interfere with the organoleptic properties. The FG-Series elements also protect membrane cartridges. As a result, they promote less maintenance and production downtime. In addition, ARNS Filter’s short lead times limit the amount of on-hand inventory required by the user.

PES MEMBRANE CARTRDGE

Our range of PES membrane cartridges, such as, GFPES, GBPES, and GDPES are 100% integrity tested before leaving the manufacturing facility to ensure they adhere to bacterial removal standards. The end-users process and operating requirements will dictate which ARNS Filter PES product and what micron rating is most optimal. This is often determined by the type of beer produced.

Frequently Asked Questions

What is beer filtration and how does it work?

Beer filtration is the process of removing any remaining solid particles, yeast, and other impurities from the beer after it has been brewed. This is typically done to improve the clarity, stability, and shelf life of the beer. This is achieved by passing beer through a filter such as a depth filter, pleated filter, or membrane filter, which traps or retains particulate and removes them from the beer.

What are the benefits of beer filtration?

Filtration is important because it improves the clarity, flavor stability, and shelf life of the beer making it appealing and safe for consumption. Filtration can also help to remove unwanted flavors, aromas, and colors, resulting in a cleaner, more consistent beer. In addition, beer filtration can help ensure regulatory compliance and impve consumer perception of the product.

What are the different types of beer filtration?

There are several types of beer filtration, including depth filtration, surface filtration, and membrane filtration. Depth filtration uses a bed of filter media or filter cartridges to trap impurities, while surface filtration uses a membrane or cartridges to remove particles. Membrane filtration involves passing the beer through a media that allows only specified particle sizes to pass through. ARNS Filter offers depth filters, pleated depth filters, and membrane filters for your brewing processes.

How do I choose the right beer filtration equipment for my brewery?

Choosing the right filtration equipment depends on several factors, including the size of your brewery, the type of beer you produce, and your budget. ARNS Filter offer a wide range of filtration products, including cartridge filters, membrane filters, and filter vessels. Our team of experts can work with you to select the right equipment for your needs and provide training and support to ensure optimal performance.

How often should I clean and maintain my beer filtration system?

The frequency of cleaning and maintenance for your beer filtration system will depend on the equipment you use, the volume of beer you produce, and the quality of your source water. It’s important to follow the manufacturer’s recommended cleaning and maintenance procedures to ensure optimal performance and longevity of your equipment. In general, it’s recommended to clean and sanitize your beer filtration system after each use to prevent contamination and maintain quality.

Can beer filtration impact the taste of my beer?

Beer filtration can help remove unwanted flavors, aromas, and colors from beer, resulting in a cleaner, more consistent product. However, over-filtration can also strip beer of its natural character and even remove deisreable components like hop oils and proteins. Find the right balance between clarity and flavor is important, and ARNSFilter can help you achieve that balance with our range of filtration products and expertise.

Do all beers need to be filtered?

No, not all beer needs to be filtered. Some styles of beer, such as wheat beers and Belgian-style beers, are traditionally unfiltered and may even have a cloudy appearance. However, most commercial beers are filtered at some point to improve clarity and stability.

What are the best practices for beer filtration?

Some best practices for beer filtration include regularly monitoring and adjusting filtration parameters, maintaining a clean and sanitized filtration system, using quality filter products and equipment, and properly storing and handling filtered beer.

What is the cost of beer filtration equipment?

The cost of beer filtration equipment and installation can vary depending on the type and size of equipment needed, as well as the complexity of the installation. ARNS Filter offers competitive pricing on our range of filtration products and can provide a customized quote based on your specific needs.

How does filtration affect the clarity and color of beer?

Beer filtration can improve the clarity and color of beer by removing suspended particles that can make the beer appear hazy or cloudy. However, it’s important to find the right balance between clarity and flavor to ensure that the beer retains its desired characteristics.

What are some common challenges with beer filtration and how can they be addressed?

Some common challenges include clogging of the filter, inconsistent product quality, and microbial contamination. To address these challenges, it is important to ensure that the filter is properly sized and maintainedm and that the beer is properly conditioned and filteres at the appropriate temperature and pressure. Additionaly, it may be necessary to adjust the filtration process, such as flow rate and filter media, to achieve desireable levels of clarity and consistency. Regular monitoring and analysis of the beer quality and filter performance can alos help to indetify and address any potential issues.

Contact

- Infiflow ARNS Technofilters Pvt. Ltd.

- RACHETA SOCIETY NIGDI, Yamuna nagar, Pune City, Pune- 411044, Maharashtra

- © Copyright 2025, arnstechnofilters.com