Construction Materials

- Membrane: Polyethersulfone

- Support Media: Polypropylene

- End Caps: Polypropylene

- Center Core: Polypropylene

- Outer Support Cage: Polypropylene

- O-Rings/Gaskets: Buna, EPDM, Silicone, Teflon® Encapsulated Viton®, Viton®, Teflon® Encapsulated Silicone

Operating Conditions

- Change-Out ΔP (recommended): 35 PSID

- Temperature (max): 176˚F (80˚C)

- Differential Pressure (max): 72 PSID (3.4 bar) at 68˚F (20˚C)

Sterilization

- Hot Water: 85-95˚C for 30 min., max dP 7 PSI

- Steam Sterilization: 134˚C for 30 min., max dP 7 psi; 100 cycles

Toxicity

All polypropylene components meet the specifications for biological safety per USP Class VI – 121 ̊C for plastics.

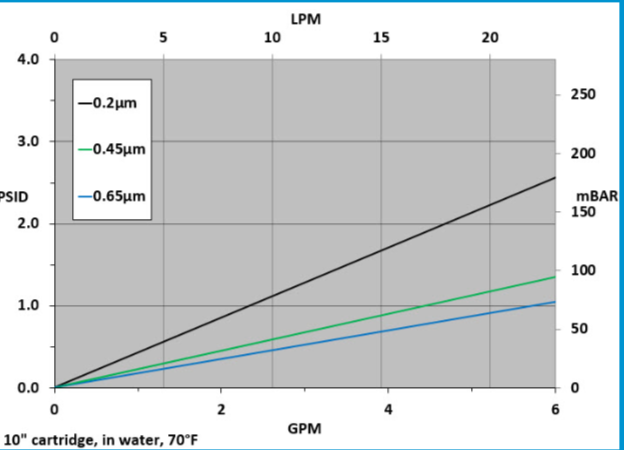

Flow Rate vs Pressure Drop

Dimensions

- Length: 10 to 40 inches ( 254 to 101.6 cm) nominal

- Outside Diameter: 2.70 inches (7.0 cm) nominal

Food Safety Compliance

Materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations, 21CFR. Materials used to produce filter media and hardware are deemed safe for use in contact with foodstuffs in accordance with EU Directives 1935/2004, and/or 10/2011.

BRPES-Series Ordering Specifications

| Rating (μ) | 0.2, 0.45, 0.65 |

| Length | 10″, 20″, 30″, 40″ |

| End Cap Style | 2 = DOE Flat Gasket 3 = 222 w/ Fin 4 = 22 w/ Flat Cap 6 = 226 w/ Flat Cap 7 = 226 w/ Fin 28 = 222 3-Tabs w/ Fin |

| O-Rings/Gaskets | B = Buna-N E = EPDM S = Silicone T = Teflon® Encapsulated Viton® V = Viton® Z = Teflon® Encapsulated Silicone |

Microbial Retention Performance

| Rating | Challenge Microbe | Log Reduction Value |

| 0.2μ | Brevundimonas diminuta | >8.0 |

| 0.45μ | Lactobacillus lindneri, Serratia marcescens | >8.0 |

| 0.65μ | Lactobacillus lindneri, Saccharomyces cerevisiae | >8.0 |