Typical Applications

- Food & Beverage

- Deionized Water

- Process Water

- Fine Chemicals

- R.O. Pre-Filtration

- Wastewater

- Produced Water

- Wine Clarification

- Sweeteners

Construction Materials

- Filtration Media: Borosilicate Microglass with acrylic binder

- Support Media: Spun-bonded Polyester

- End Caps: Polypropylene

- Center Core: Glass-filled Polypropylene

- Outer Support Netting: Polypropylene

- O-Rings/Gaskets: Buna, EPDM, Silicone, Teflon® Encapsulated Viton®, Viton®

- Outside Diameter: 2.5″

Operating Conditions

- Change Out ΔP (recommended): 35 PSID

- Temperature (max): 176˚F (80˚C)

- Differential Pressure (max): 60 PSID (4.1 bar) at 68˚F (20˚C)

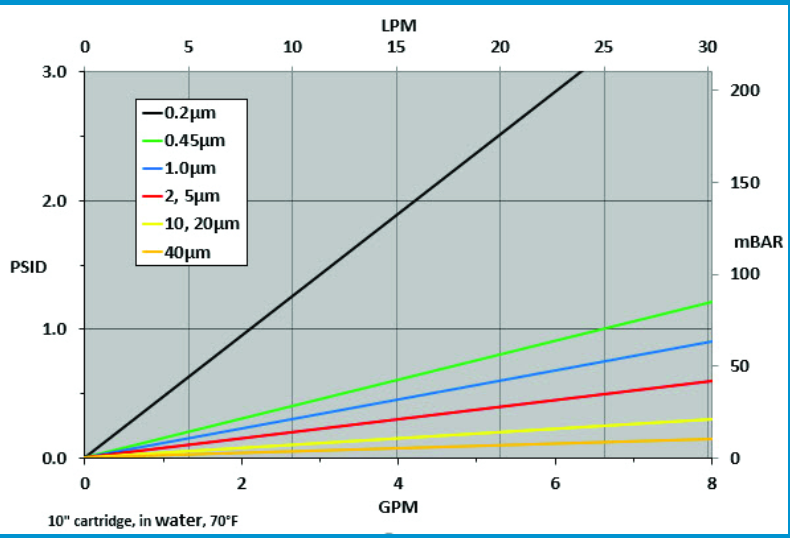

Flow Rate vs Pressure Drop

Food Safety Compliance

Materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations, 21CFR. Materials used to produce filter media and hardware are deemed safe for use in contact with foodstuffs in accordance with EU Directives 1935/2004, and/or 10/2011.

FGE-Series Order Specifications

| Micron Ratings | 0.2, 0.45, 1.0, 2.0, 5.0, 10.0, 20.0, 40.0 |

| Retention | N=Nominal A=Absolute |

| Lengths | 10″, 20″, 30″, 40″ |

| End Cap Style | 2 = DOE Flat Gasket 3 = 222 w/ FIN 4 = 222 w/ Flat Cap 5 = 222 w/ Spring |

| O-Rings/Gaskets | B = Buna E = EPDM S = Silicone T = Teflon® Encapsulated Viton® V = Viton® |

| Adders (Optional) | CS = 316SS Compression Spring I = Stainless Steel Insert SS = Stainless Steel Core |