- 9:00 am to 6:00pm

Pulp and Paper Industry

- Home

- Pulp and Paper Industry

Pulp and Paper Industry

Since the company’s inception, ARNS Filter has been a leading supplier of liquid filtration solutions for pulp and paper mills. Reliable, quality products coupled with a customer-centered focus are reasons why ARNS Filter is trusted by each of its customers. ARNS Filter’s filtration solutions help improve process reliability, and product quality and reduce operating costs.

Since the company’s inception, ARNS Filter has been a leading supplier of liquid filtration solutions for pulp and paper mills.

The ARNS pulp and paper market size is projected to reach USD 368.10 billion by 2027. ARNS Filter products are widely used in the pulp and paper industry as they help attain the specific needs of various applications while providing extended service. Our target applications in the paper-making process are point-of-use condensate recovery water, chemicals (paper additives and bleaching solutions), boiler feed, potable water (incoming water, spray nozzles, knives, eye wash stations), hydraulic and lubrication applications. Reliable, quality products coupled with a customer-centered focus are reasons why ARNS Filter is trusted by each of its customers. ARNS Filter’s filtration solutions help improve process reliability, and product quality and reduce operating costs.

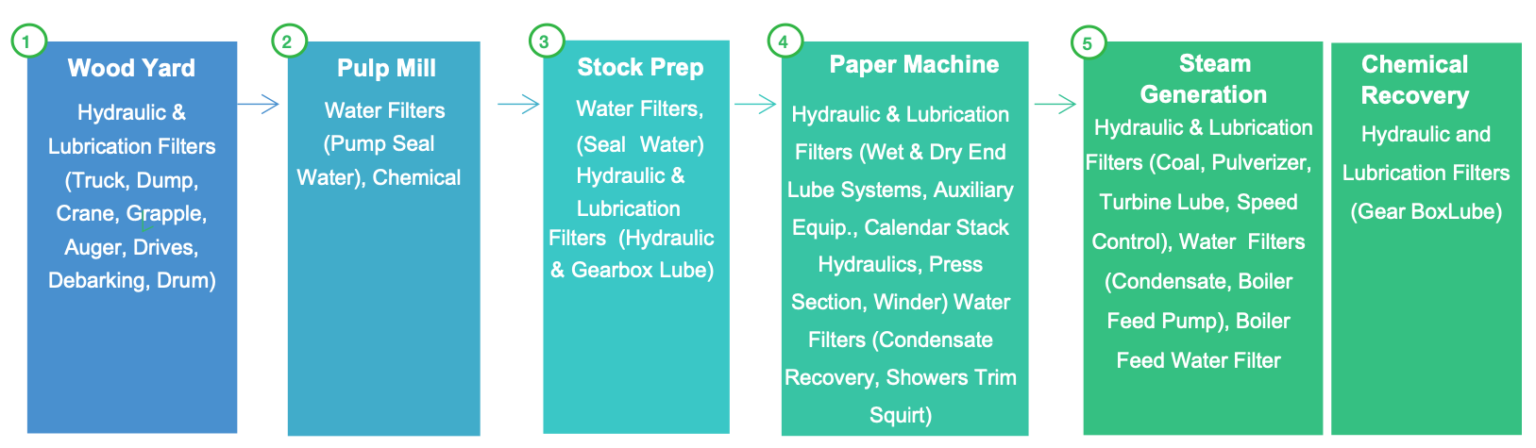

Typical Pulp and Paper Process

Pulp and Paper Process Fluid Filtration Solutions

Meltblown Filters – varying grades, both nominal and absolute rated, can be used to meet the demands of many types of process fluids.

Pleated Depth Filters – polypropylene, microglass, and polyester options to a variety of demanding process conditions.

Pleated Membrane Filters – polysulfone and polyethersulfone products can be used for water recovery, water polishing, and chemical filtration prior to product mixing.

Boiler Feed & Potable Water Filter Solutions

Our complete range of meltblown depth, Pleated Depth, and Pleated Membrane filter cartridges solutions for water treatment systems reduce and remove minerals, pathogens, and a variety of harmful contaminants.

Hydraulic and Lubrication Oil Filter Solutions

Pleated Depth products can be used to purify lubrication oils and protect lubrication systems while withstanding intense process conditions.

Paper and Pulp Filtration System Products

Depth Cartridges

With its gradient density depth construction, our depth cartridge products are an economical option for the removal of both fine and coarse deformable and non-deformable contaminants. Ideal for use as a prefilter, protecting costly downstream pleated cartridges/equipment, or as a final filter in a wide variety of industries and applications.

Pleated Depth Cartridges

The multi-layer, fiber-based medias provide true depth-loading for high-efficiency removal at low micron ratings. Pleated depth cartridges design increases surface area which in turn, increases loading capacity and allows for higher flow rates. In a typical process flow, used as a prefilter to pleated membranes or as a polishing element to depth style medias.

Contact

- Infiflow ARNS Technofilters Pvt. Ltd.

- RACHETA SOCIETY NIGDI, Yamuna nagar, Pune City, Pune- 411044, Maharashtra

- © Copyright 2025, arnstechnofilters.com